“That’s the Porsche philosophy,” says Michael Behr. The technical project manager is responsible for orchestrating the different disciplines involved in the Mission R, and keeping a steady eye on feasibility. “This prototype is, of course, a show car at this point, yet it also meets the highest technical standards.”

Implementation of the Porsche strategy

Beneath its shell, the car represents the fulfilment of Porsche’s strategy on sustainability and social responsibility. While the company is already operating on an all-electric basis in Formula E, uses synthetic fuels in the Porsche Mobil 1 Supercup, and is developing a new hybrid racer for endurance events, the Mission R is now bringing electric technology to customer racing as well.

Porsche rarely shows such futuristic concept cars. But when it does, it often culminates in a resounding success. Take the Boxster: the original concept was presented in Detroit in 1993. Or the Carrera GT, which Walter Röhrl drove in front of the Louvre in Paris in 2000. The 918 Spyder concept car followed in 2010, this time in Geneva. The forerunner to the Taycan, the Mission E, debuted at the IAA in 2015. Behr was also on board for that project. “These are jobs with massive deadline pressure,” he admits, “yet at the same time they’re engineers’ dreams come true that start with a blank sheet of paper.” There’s no model for the Mission R. It is the model.

Thinking it all the way through

For Porsche’s standards, it is not enough just to build a rolling chassis that merely gives shape to a vision from the design department. The spirit of Weissach demands performance in concept cars as well. During the creation process, every step of the computer-aided design (CAD) process is carried out with the same attention to quality as if it were a pre-production vehicle.

The Mission R boasts all-wheel drive and 800 kW (1,088 PS). The power is supplied by two electric motors, manufactured in Zuffenhausen along with the single-speed transmission. With a target weight of less than 1,500 kilograms, the sports car should manage the sprint from 0 to 100 km/h in less than 2.5 seconds. Depending on the choice of gear ratio, the top speed clocks in at more than 300 kmh.

Direct cooling of the stator

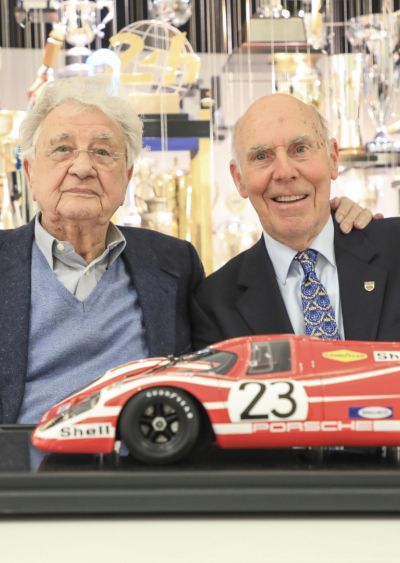

Thanks to the direct cooling of the stator – the stationary element of the electric machine in which the rotor rotates – the units deliver exceptionally high continuous power. The futuristic racing car makes do with just one oil cooling circuit and without a single drop of water. The direct oil cooling of the high-voltage battery is based on an innovation developed for the three-time Le Mans winner, the Porsche 919 Hybrid. The chassis, too, is advanced racing technology and features a double-wishbone front axle. A heated windshield has even been fitted for good visibility in the wet.

“At the same time, we did our utmost to leverage the last bit of lightweight potential in every detail,” says Behr. For example, the 3D-printed transmission case cover is 30 per cent lighter than a cast one. The additional braking power during recuperation made it possible to shave 12 kg off the braking system. The composite outer skin is not just feather-light, but also sustainable: it consists mainly of natural fibre, supplemented by carbon fibre components.

Craftsmanship from Weissach

Weissach is renowned for excellent engineering, and also for craftsmanship. The chassis of the secret prototype was built in Flacht, in the racing department. It later moved within Weissach to Building 100 – a high-security facility beneath the studio of Style Porsche. This is where the exterior form and the interior were created.

Between these stops, the visionary chassis has to venture out into the fresh air – still without a protective body. The skid pan of the in-house test track is on the agenda. This first functional test, less than six months before the car’s premiere at the IAA, represents a key milestone. It doesn’t matter that many components are still provisional at this point. A steel subframe will suffice for the roll-out; the final composite cage has yet to be created. The seat, steering wheel, and pedals are still borrowed from existing racing cars, while the rims still lack the central lock hubs.

The car that Lars Kern is driving seems rather naked at this point. The man himself is relatively lightly clad as well – the colleagues around him are still wearing thick down jackets on this cold spring day. “There are certainly warmer days,” the development engineer recalls with a laugh, “but there are also significantly worse ones. Having the chance to participate in a project like this is such an emotional experience. I was like a kid in a candy store!” Time and again he steers the raw machine out onto the test track. A few sets of tyres later, the brake balance between the front and rear axles is sorted as well. “What surprised me the most was how advanced the car already was. And of course the immediate availability of tremendous torque and overall driving dynamics. At that point it was clear: what’s being created here is going to be a lot of fun.”

Article republished from Porsche NewsRoom